We’ve all done it. You take out the tape measure, mark your cut line, make the cut…only to come up short. Maybe for you it was hanging a picture too high, or you used two tablespoons instead of teaspoons, or perhaps eye-balling the doorway to make sure the couch would fit through. The feeling is the same regardless – frustration. Frustration for not taking the time to get all the information you need to make the right decision the first time (and for having to repaint the door frame now).

Modern construction projects have nearly as many people involved in the process as they do physical parts. The owner, design team, general contractor, subcontractors, consultants, material suppliers, inspectors, the list goes on and on. All of which have experienced the pain of not measuring twice and all of which are relying on 2D contract drawings and specifications to tell them what is needed to get the job done. Modern day teams are finding tremendous value in having a coordinated 3D building information model (BIM) as their “second measurement” needed to get things right the first time.

We’re going to go through some examples of how BIM can bring value to your project and process, but to do that we have to make sure we’re talking about the same thing. BIM is not referring to a specific piece of software (looking at you, Revit) nor a flashy 3D rendering you show your friends and colleagues to impress them. It is the process wherein we design professionals digitally “build” the building before it’s built by our partners in the field. Much like construction projects, building information models vary to fit the needs of the task at hand. What you might need for a brand new 15-story residential complex could be quite different when compared with the 1-story interior renovation of a historic library. Let’s look at few ways that BIM can help you be the rockstar on your next project:

Design Assist – Hold your hand up if you’ve ever felt like a set of 2D contract drawings gave you everything you could possibly need to get something constructed? Me neither. By the time you have your contract in your hand you’re already two weeks behind and now you’ve got to submit all these RFIs. Now imagine a scenario where you were engaged weeks or months earlier to help provide guidance to the design team directly about the building you’re expected to put together. BIM enables contractors and specialty engineers to work together to solve complex challenges presented on projects in a way that is both cost-effective and constructable, before you order your materials.

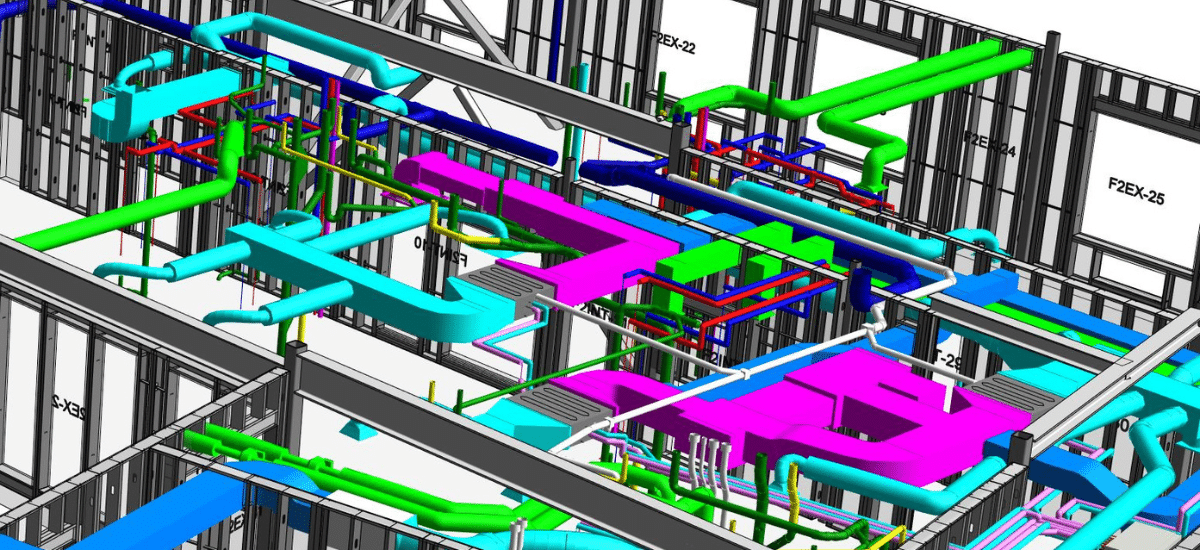

Clash Avoidance – With many trades vying for the same space in a corridor ceiling, one may believe that a duct running through a door jamb was inevitable. We’re here to tell you that it doesn’t have to be. The process of coordinating a 3D building model with various trades involved, authoring their designs in their software of choice, is no small feat yet it yields incredible results. When the trades come together to review their work in a collaborative environment, it gives everyone the opportunity to find the best possible outcomes.

Prefabrication Model & Drawings – Now we’re getting to the fun stuff. Prefabrication of various parts of a building enables a contractor to assemble those parts in a controlled environment and provides many unique opportunities. Aside from not having to worry about the rain or snow, being able to build portions of the work in advance and snap it together on-site like a Lego set lets you get your work installed quickly, safely, and allows for a level of quality control that wouldn’t have been possible had it been fully constructed on-site alone. Building information models that are developed for prefabrication purposes are created at a higher level of detail (LOD 400+) which further pushes the benefits of the clash avoidance process by ensuring all parts and pieces are accounted for, but also can help by supplying complete material cut lists and even machine-ready data that can be fed directly into your CNC or rolling machines.

Existing Conditions – Whether you’re working on a renovation of an existing facility and need to locate all existing structural elements or are required in your contract to provide an as-built model with installed framing updated to real-life locations, BIM enables you to meet these challenges with confidence. Laser scanning, photogrammetry, LiDAR, drones, etc. allow us to capture the reality of the project in its current state with incredible accuracy and incorporate that into or compare it against a building information model to ensure there are no surprises (ok, less surprises) when you get on-site.

BIM is not simply a tool in the toolbox, but rather a complete approach to designing a building more efficiently with better consideration of constructability and communicating that design to everyone involved. Instead of looking at BIM as an annoying requirement you must meet as part of your contract, use it as an opportunity to measure twice so you only need to cut once. By partnering with McClure, you are choosing a team of experts who are passionate about using BIM to build a brighter future for your construction projects. Let’s work together to bring your vision to life.

Tyler McNally

Tyler McNally is McClure’s BIM Services Manager with 14+ years of experience in the cold-formed steel design industry. His specialties range from the development of cold-formed steel shop drawings and prefabricated panel tickets, clash resolution between trade partners, development of drafting/modeling standards, and direct coordination with clients to determine project needs. You can contact Tyler at tmcnally@mcclurevision.com.

Learn More

Learn more about McClure’s BIM services or contact us at info@mcclurevision.com.