McClure Engineering Company (MEC), the design engineer of record, was tasked with providing the initial survey, concept study and report, preliminary and final design, construction staking, observed construction, and the final as-built survey and drawings. The concept study reviewed the projected traffic along the roadway to establish the number of required lanes and analyzed the intersection to determine if there should be a stop sign-controlled intersection, a signaled intersection, or a roundabout. The City opted for a concrete roundabout with colored, stamped concrete truck aprons and crosswalks.

The preliminary plans also proposed two paving options: concrete and asphalt. “The City wanted the roundabout to be concrete, but the mainline had a base bid of asphalt and an alternate bid of concrete,” said Paul Parks, P.E., senior project engineer on Clear Creek Parkway.

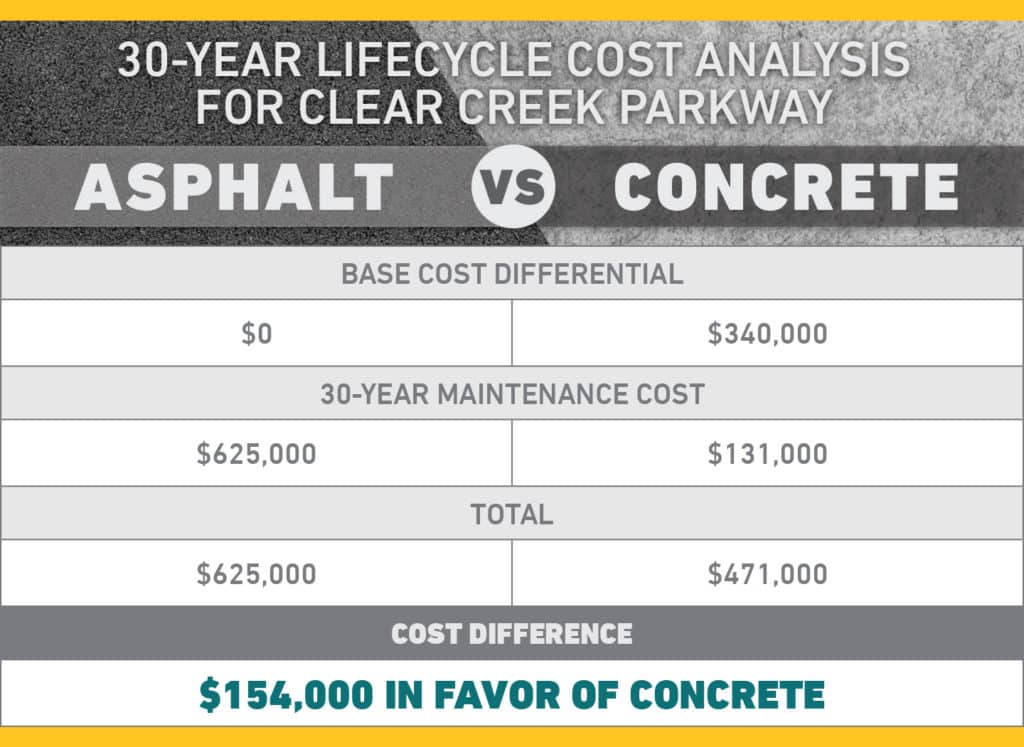

The City of Shawnee evaluated its paving options by performing a 30-year lifecycle cost analysis. It reviewed the total economic worth of the project by analyzing initial and discounted future costs, which included initial construction, maintenance, user cost, reconstruction, rehabilitation, restoration, resurfacing, and salvage value.

One of the initial construction costs evaluated was the pavement. Asphalt is often an economical solution for paving roads, but as an oil-based product, it can be affected by the market price of petroleum. When the City of Shawnee made its analysis in January 2017, oil prices averaged $2.46 per gallon—about 40 cents per gallon more than January 2016, according to the U.S. Energy Information Administration. With higher oil prices, the playing field was leveled for both paving options.

Estimated construction costs prior to bidding were $4,895,600.79 for the asphalt option and $5,125,010.19 for concrete. Although the base cost differential was $340,000 more for concrete, the maintenance costs were significantly less over 30 years.

“With asphalt you have the initial installation, then the mill and overlay costs that will occur two or three times over the 30-year period, plus the annual crack sealing,” Parks said. “Concrete has a higher initial cost, but there is no pavement replacement during that time and only minor crack sealing.”

Asphalt maintenance was estimated to be $625,000 over three decades, while concrete maintenance would be approximately $131,000. Despite the higher initial cost for concrete, it would actually save the City of Shawnee nearly $154,000 to pave the parkway with concrete.

Design Differences

Clear Creek Parkway’s concrete roundabout.

For MEC engineers, the roadway design did not have to be altered when the paving material was selected, but the height of the paving sections was different. On Clear Creek Parkway, the asphalt needed to be 9 inches high, while the concrete only needed to be 8 inches. “The earthwork numbers are different based on that inch,” Parks said.

The concrete design did not affect the horizontal and vertical alignment, turns, or intersection, but MEC engineers were required to incorporate a joint layout and show where the saw cut lines were located.

“The joint layout can be tricky, because there are a lot of little criteria for it going into the intersection and roundabout,” Parks said. “There are round lines and straight lines, and we had to figure out how to blend them together.”

The joints control cracking, and steel at the joints provide load transfer to keep the pavement smooth and quiet. They also provide an aesthetic visual effect.

Benefits of Concrete

Paving roads with concrete isn’t new. According to the Portland Cement Association (PCA), the first concrete street was built in Ohio in 1891, and it is still in service today. Mass production of concrete and steel after World War II enabled substantial growth of concrete-paved state highways, rural roadways, residential streets, and parking lots. Concrete roads are found in nearly every environment and climate, from the freezing winters of the upper Midwest to the dry heat of the Southwest.

Cities that opted for concrete roadways in the 1950s and 1960s continue to benefit from their durability. “In my hometown of Lawton, Okla., all the residential streets are paved with concrete,” Parks said. “They are more than 60 years old and still have not been replaced.”

In addition to reduced maintenance and long lifecycles, concrete roadways have other advantages. Concrete is a mix of materials like sand, aggregate, and cement that are typically local products, which PCA said reduces transportation costs and fuel consumption for delivery. Many concrete roads, including Clear Creek Parkway, also use industrial by-products like fly ash and blast furnace slag.

Concrete’s light color makes it naturally reflective, and street lights appear brighter at night. It also doesn’t absorb as much heat as asphalt and reduces smog.

From a safety perspective, concrete roads are less susceptible to heavy-vehicle wheel ruts, and the concrete dries in as little as six hours, resulting in shorter times for lane closures. With less congestion due to fewer repairs, the risk of danger to road crews and drivers is reduced too.